Spark plug is used in all automobile engines whether it’s two

wheeler, three wheeler, four wheeler or even bigger vehicles. Spark plug is an

electrical device which is mounted on cylinder head of internal combustion

engines, this electrical spark plug generated a spark which is used to ignites

the compressed fuel uses in engines

Spark plug consists of an insulated central electrode which in

turn connected through an insulated wire to the ignition coil where ignition is

required. This insulated wire may also be connected to the magneto circuit on

the outside and form a grounded terminal on the base of the plug. A spark gap in

cylinders of and Internal combustion engines is usually divided into:-

(i)

Spark-ignition engines:-

These engines required

spark plugs to begin combustion,

(ii)

Compression-ignition engines Known as diesel engines:-

In these engines air is compressed

and then diesel fuel injection is done into the heated compressed air mixture

where fuel gets auto ignition.

Compression-ignition engines may use glow plugs to improve cold

start characteristics.

There

are following functions of Spark plugs:-

There are two primary functions of Spark Plugs

(i)

To ignite the air/fuel mixture.

As discussed earlier electrical spark generated through spark

plug , this spark jumps the air gap when voltage applied to spark plug is high

enough for crossover of air gap. This spark is used to ignite the air/ fuel

mixture in combustion chamber.

(ii)

Removal of heat from Combustion chamber:-

There is misconception that spark plugs create heat but spark

plugs are used to remove hear instead. Temperature at the end of spark plug

i.e. firing end must be kept low to such levels so as to prevent pre-ignition. Also

it should be kept in mind that temperature must not be so high so

as to prevent unwanted firing.

The

heat range of the spark plug must be carefully selected as if heat range is not correct we will face

of troubles. Spark plug firing end temperature is between 900-1,450 degrees. If

<900 degrees, carbon polluting is possible. If Temperature is >1500

degree than overheating becomes an issue.

Spark plug acts as a heat exchanged i.e. removes non-useful

thermal energy from combustion

chamber and transfers that heat into engine cooling system.

Ability of spark plug to remove heat from spark plug tip and is

called as heat range.

Operation of Spark

plug :

The spark plug is connected to ignition coil or magneto high

voltage generation end. Due to this high voltage at one end there will be

potential difference between center of electrode and side electrode. Now due to

air gap ignition doesn’t happen now when voltage level reaches to high level

then air fuel mixture get ionized and at certain level whole air fuel mixture

get ionized and this ionized gas becomes good conductor of electricity and this

ignites spark across gap.

Voltage required to generated spark is usually of the level of

20KV-100KV.

When air gap get ionized such that current starts flowing across

gap then , temperature level attained will be around 60000 K. This extreme heat

causes the expansion of air and fuel mixture to expand more quickly and there

will be small explosion.

There

are two type of spark plus:-

(i)

Cold Spark plugs

(ii)

Hot spark plugs

Cold

Spark Plugs:-

In

these spark plugs heat flow path is short. It is shortened so that there will

be faster heat transfer and also you can find small insulator nose on these

spark plugs and surface area of this insulator nose is smaller. Due to smaller

surface area high heat absorption could not occur in these spark plugs.

Hot

Spark Plugs:-

These spark plugs have longer insulator nose

so longer heat transfer path. As there is longer heat transfer path so which

leads to slower heat transfer to the surroundings cylinder heads.

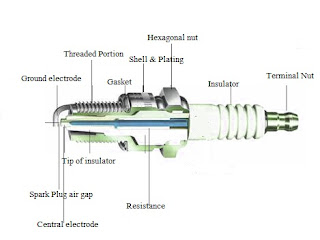

There are following

parts of spark plugs:-

(i)

Insulator

(ii)

Hexagonal

(iii)

Shell & Plating

(iv)

Gasket

(v)

Threads

(vi)

Ground electrode

(vii)

Central electrode

(viii) Spark plug electrode gap

(ix)

Insulator nose or end tip of insulator

(x) Terminal nut

(xi) Resistance

(i)

Insulator: Insulator body is usually made from Aluminum oxide ceramic.

Then high pressure dry molding technique is used for construction of insulator.

When molding is done then it is fired in kiln to temperature that even exceeds

the melting point of steel, by doing this insulator will properties such as

high dielectric strength, excellent resistance to shock and very high thermal

conductivity. On outer surface of spark plug circles so as to provide grip of

spark plug.

(ii)

Hexagonal:-This is provided as to provide grip of fixing the spark plug at

required place and tightening of spark plug is done from that point only.

(iii)

Shell and Plating:- Shell is just below hexagonal and is made using

special cold extrusion process. Now this shell is plated to provide protection

against the rust and corrosion.

(iv)

Gasket:- These may or may not be used in spark plugs. Where gasket is

used in Spark plugs there gasket is having folded steel design that provides a

smooth surface for sealing purposes. Spark plugs without gaskets have a tapered

seat shell which seals through close tolerance.

(v) Threads:- Threads are used to mount the spark plug at specified location

and these threads are made though rolling process instead of cutting the same.

(vi)

Ground electrode: Ground electrodes are made from nickel

alloy steel and made into different shapes. Property of ground electrode is

that under extreme temperature and pressure conditions ground electrode be resistant

to both spark erosion and chemical erosion.

(vii) Center electrode:- Central electrode also should have same properties as that of ground

electrode i.e. it must sustain extreme temperature and pressure conditions.

(viii) Electrode gap:-The gap between ground electrode and center electrode is known

as spark plug electrode gap. Gap should be kept as minimum as possible but

could not touch the tip of insulator as required spark will not produce in that

case.

(ix) Insulator nose or end tip

of Insulator:-There

are carbon deposits with passage of time on insulator tip due to sparks

generated during period of operation so spark plug nose shape and size is such

that it should be capable of removing carbon content, oil and fuel deposits.

(x) Terminal Nut:- There are two options available in spark plug for connections

i.e. spark plug comes with terminal nut or without terminal nut i.e. with

threaded nut and connection type or even both. Terminal nut can be detached

from spark plug.

(xi) Resistance:- Resistance is provided to high voltage provided to spark plugs

so that current could not be very high. Resistance is also kept in thousands. Resistance

vary from 1000- 7000 ohms. 5000 ohm is usually cut of point for because it

provides a value between where spark plugs are manufactured and where problems

seem to appear with high resistance. Most reports Tempest receives about rough

running engines associated with high spark plug resistance involve values of

7000 ohms or more.