Bushings are very important component

of Transmission system. These are used of providing insulation to equipment.

There are various types of

bushings available in the market, bushings are classified according to

following:-

(i)

Type of insulating material used

(ii)

Type of construction

(iii)

Insulation inside bushing

Let’s discuss about the same:-

(i)

Type of Insulating Material

Used:-

This classification depends

primarily on the application of the bushing, i.e. the purpose for which bushing

is used. These can be further classified as:-

(a)

Air-to-oil bushing

In this type of bushing there is

air is used as insulation at one end on bushing and oil acts as insulation at

other end. In these bushings oil end is approximately half as long as air end

as oil dielectric strength is more than two times than air at atmospheric

pressure.

(b)

Air-to-air

bushing

In This type of bushing air acts as insulation at both ends and is

used for applications where at end is open to atmospheric conditions and other

is at indoor conditions.

(c)

Air-to-SF6

bushings

This type of bushing is used for

SF6 insulated circuit breakers.

(d)

SF6-to-oil

bushings

This type of bushing is used as

shift from SF6 bus ducts and oil filled equipment.

(e)

Oil-to-oil

bushings

This type of bushing as

transition between Oil bus ducts and oil filled equipment.

(ii)

Type of

Construction:-

There are two types of bushings

depending upon type of construction, these are classified as below:-

(a) Solid

Type bushings also known as Bulk type bushings

(b) Capacitance

graded bushings also known as Condenser type bushings

Let’s discuss about these:-

(a)

Solid Type bushings:-

The kind of bushing, is normally

made with a focal conductor and porcelain or epoxy covers at either end and is

utilized essentially at the lower voltages through 25 kV. These bushings are generally utilized as a

part of utilizations extending from little distribution transformers and

circuit switchgears to vast generator venture up transformers and

hydrogen-cooled control generators.

The essential impediment of the

strong bushing is its capacity to withstand 60-Hz voltages over 90 kV.

Henceforth, its applications are restricted to 25-kV hardware appraisals, which

have test voltages of 70 kV. Late applications require low halfway release

confines on the 25-kV terminals amid transformer test and have brought about

additional limitations on the utilization of this sort of bushing.

In these cases, either an

extraordinarily outlined strong bushing, with one of a kind evaluating

protecting that empowers low innate halfway release levels, or a more costly

capacitance-reviewed bushing must be utilized.

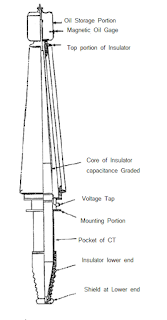

(b)

Capacitance

Graded Bushings:-

These bushings are utilized for

basically all voltage evaluations over 25-kV voltage and has been utilized for

bushings upto 1500-kV voltage.

These bushings utilizes directing

layers at foreordained spiral interims inside oil-impregnated paper or some

other protection material that is situated in the space between the focal

conductor and the protector.

Diverse makers have utilized an

assortment of materials and techniques for making capacitance-evaluated

bushings. Early techniques were to embed concentric porcelain barrels with

metallized surfaces or overlaid pressboard tubes with installed conductive

layers. Later outlines utilized conductive foils, commonly aluminum or copper,

in oil-impregnated kraft paper.

An elective strategy is to print

semiconductive ink (distinctive producers have utilized diverse conductivities)

on all or a portion of the oil-impregnated kraft-paper wraps.

The primary components are the

focal round conductor, onto which the capacitance-evaluated center is wound;

the best and lower protectors; the mounting rib; the oil and an oil-extension

top; and the best and base terminals.

Capacitance-reviewed bushings

include numerous more specialized and assembling subtle elements than strong

bushings and are hence more costly. These points of interest incorporate the

protection/directing layer framework, gear to wind the capacitor center, and the

oil to impregnate the paper protection.

In any case, it ought to be

noticed that the outspread measurement required for the capacitance-evaluated

bushing is considerably less than the strong development, and this saves money

on material inside the bushing also in the mechanical assembly in which the

bushing is utilized. Likewise, from a down to earth stance, higher-voltage

bushings couldn't in any way, shape or form be fabricated with a strong

development.

(iii)

Type of

Insulation inside Bushing

Still another order identifies

with the protecting material utilized inside the bushing. As a rule, these

materials can be utilized as a part of either the strong or

capacitance-evaluated development, and in a few sorts, more than one of these

protecting materials can be utilized as a part of conjunction. The accompanying

content gives a short portrayal of these sorts:

1. Air-Insulated Bushings

Air-protected bushings for the

most part are utilized just with air-protected mechanical assembly and are of

the strong development that utilizes air at air weight between the conductor

and the protectors.

2. Oil-Insulated or Oil-Filled Bushings

Oil-protected or oil-filled

bushings have electrical-review mineral oil between the transmitter and the

encasings in strong sort bushings. This oil can be contained inside the

bushing, or it can be imparted to the contraption in which the bushing is

utilized. Capacitance-reviewed bushings likewise utilize mineral oil, typically

contained inside the bushing, between the protecting material and the

protectors for the motivations behind impregnating the kraft paper and

exchanging heat from the directing lead.

3. Oil-Impregnated Paper-Insulated Bushings

Oil-impregnated paper-protected

bushings utilize the dielectric cooperative energy of mineral oil and electric

evaluations of kraft paper to deliver a composite material with predominant

dielectric-withstand attributes. This material has been utilized broadly as the

protecting material in capacitance-evaluated centers for approximately the most

recent 50 years.

4. Gum Bonded or - Impregnated Paper-Insulated Bushings

Gum fortified paper-protected

bushings utilize a sap covered kraft paper to manufacture the

capacitance-reviewed center, while gum impregnated paper-protected bushings

utilize papers impregnated with tar, which are then used to create the

capacitance-evaluated center. The last kind of bushing has prevalent dielectric

attributes, equivalent with oil-impregnated paper-protected bushings.

5. Cast-Insulation Bushings

Cast-protection bushings are

developed of a strong thrown material with or without an inorganic filler.

These bushings can be both of the strong or capacitance-evaluated types,

despite the fact that the previous sort is more illustrative of present

innovation.

6. Gas-Insulated Bushings

Gas-protected bushings utilize

pressurized gas, for example, SF6 gas, to protect between the focal conductor

and the rib. It utilizes the same pressurized gas as the electrical switch, has

no capacitance reviewing, and utilizes the measurements and situation of the

ground shield to control the electric fields.

Bushing rating and mounting are

depended upon type of interface. HT

Bushing above 1000 V are designed as per IS 2099

There are 5 types of interfaces:-

1. Interface

A1

2. Interface

B1 & B2

3. Interface

C1 & C2

4. Interface

D1 & D2

5. Interface

F1, F2 & F3

Short circuit ratings of all

above mentioned bushings is as below:-

|

Interface Type

|

Contact Type

|

Current Rating(A)

|

RMS(kA)

|

Peak asymmetrical current rating kA

|

||

|

1 Sec

|

2 Sec

|

3 Sec

|

||||

|

A1

|

Pin and Socket

|

250

|

12.5

|

9.0

|

7.5

|

31

|

|

B1

|

Pin and Socket

|

250

|

12.5

|

9.0

|

7.5

|

31

|

|

B2

|

Pin and Socket

|

400

|

16.0

|

11.3

|

9.2

|

40

|

|

C1

|

Bolted

|

630

|

28.0

|

19.7

|

16.1

|

70

|

|

C2

|

Bolted

|

1250

|

75.0

|

53.0

|

43.3

|

>150

|

|

D1

|

Bolted

|

800

|

50.0

|

35.3

|

28.8

|

125

|

|

D2

|

Bolted

|

1250

|

75.0

|

53.0

|

43.3

|

>150

|

|

F1

|

Bolted

|

2500

|

-

|

-

|

-

|

-

|

|

F2

|

Bolted

|

630

|

28.0

|

19.7

|

16.1

|

70

|

|

F3

|

Bolted

|

1250

|

75.0

|

53.0

|

43.3

|

>150

|

Applications of different types

of bushings:-

A1 Interface type bushings :-

These types of bushings are

useful for equipment insulated with oil fluids such as Transformers,

Switchgear, Capacitors. There are

following types of A1 interface type bushings:-

(i) 180AR-1

(i) 180AR-1

Voltage Rating- 12 KV, Current

Rating- 250A, Dimensions are- 222 X 106 (height X Breadth)

(ii) K180AR-1

Voltage Rating- 24 KV, Current

Rating- 250A, Dimensions are- 222 X 106 (height X Breadth)

(iii) 180AR-2

Voltage Rating- 12 KV, Current

Rating- 250A, Dimensions are- 284 X 168 (height X Breadth)

(iv) K180AR-2

Voltage Rating- 24 KV, Current

Rating- 250A, Dimensions are- 284 X 168 (height X Breadth)

(v) 180AR-3

Voltage Rating- 12 KV, Current

Rating- 250A, Dimensions are- 171 X 55 (height X Breadth)

(vi) K180AR-3

Voltage Rating- 24 KV, Current

Rating- 250A, Dimensions are- 171 X 55 (height X Breadth)

There is another interface A1

bushing known as In-Air bushing for dry type transformers, Motors , Switchgear

and capacitors.

Types of Bushings are

(i)

180A-24P-O

Voltage Rating- 12 KV, Current Rating- 250A, Creepage

Distance (mm)- 630 mm

(ii)

180A-24P-O

Voltage Rating- 24 KV, Current Rating- 250A, Creepage

Distance (mm)- 630 mm

Interface B Type Bushings:-

This is useful for Oil fluids

such as Transformer, Switchgear & Capacitors.

There are following types of

bushings:-

(i)

400T1

Voltage Rating- 12 KV, Current Rating- 400A

(ii)

K400T1

Voltage Rating- 24 KV, Current Rating- 400A

(iii)

M400T1

Voltage Rating- 36 KV, Current Rating- 400A

(iv)

400AR-1

Voltage Rating- 12 KV, Current Rating- 400A

(v)

K400AR-1

Voltage Rating- 24 KV, Current Rating- 400A

(vi)

M400AR-1

Voltage Rating- 36 KV, Current Rating- 400A

(vii)

400AR-2

Voltage Rating- 12 KV, Current Rating- 400A

(viii)

K400AR-2

Voltage Rating- 24 KV, Current Rating- 400A

(ix)

M400AR-2

Voltage Rating- 36 KV, Current Rating- 400A

(x)

400AR-8

Voltage Rating- 12 KV, Current Rating- 250A

(xi)

K400AR-8

Voltage Rating- 24 KV, Current Rating- 250A

(xii)

M400AR-8

Voltage Rating- 24 KV, Current Rating- 250A

There is another type of

Interface B type switch is specifically used for SF6 circuit breakers.

Similarly there are other

Interface type bushings and have same applications only difference is in their

mounting designs , voltage rating and current rating.