Search This Blog

Thursday, August 25, 2016

Fault locating methods for High and low tension cables

Sunday, July 17, 2016

Effects of Higher and lower voltage on Induction motors

Thursday, July 7, 2016

Discovery of electricity; How electricity discovered

Now days electricity is backbone of everyone life. It seems life is

electricity. There was most often curiosity in every human being that who

discovered electricity and when. Let’s read article below to know how

electricity was discovered.

As everyone knows

electricity is nothing but source of energy. Electricity is not invented as it

is form of energy and was always present. It is only discovered and most people

think that this is discovered by Benjamin Franklin but his experiments helps in

getting a connection between lightning and electricity.

Way back in 600 BC

ancient Greeks discovered that “When we rubbing fur on amber it caused

attraction between the two” thus we can say that they have discovered static

electricity.

There are so many

discoveries has been made upto 17th century such as:-

1. Invention of electrostatic generator

2. Difference between positive and negative currents

3. Classification of materials as conductors or insulators.

William Gilbert:-

In 1600 year, William

Gilbert describe that when force which some substances exert when rubbed

against each other is known as”electicus”.

Thomas Browne:-

Thomas Browne describe

the word “electricity” In his several books. His investihgations were based on

William Gilbert work.

Ben Franklin:-

A well-known experiment was done by Ben Franklin, In 1752, with

a kite, a key, and a storm. Electricity from the storm clouds transferred to the kite key and electricity flowed

down the string and gave him a shock. Luckily he get escaped unhurt so by this

he proved his idea.

Through this experiment he proved that lightning and electric

sparks are same thing.

Alessandro Volta

Volta was an Italian

physicist. He discovered that a particular chemical reaction produces

electricity. In 1800 he constructed the voltaic pile, which was an electric

battery, that produced a steady electric current also called as DC battery.

Volta also created the first transmission of electricity by linking

positively-charged and negatively-charged connectors and driving an electrical

charge, or voltage, through them.

Michael Faraday:-

Everyone know Faraday

efforts for electricity generation. In year 1831 Michael Faraday make

electricity use viable by creating the electric dynamo . Faraday’s uses a

magnet that was moved inside a coil of copper wire, creating a tiny electric

current that flowed through the wire.

Faraday also stated

Law of electromagnetic Induction for production of electricity which is basis

of today electricity generation.

In 1878 American Thomas Edison and British

scientist Joseph Swan invented the incandescent filament light bulb in their

respective countries.

In 1882 Edison used his direct-current system

(DC) to provide power to illuminate the first New York electric street lamp.

In Late 1800’s and

early 1900’s inventor Nikola

Tesla became an important contributor to the birth of commercial electricity.

He also worked with Edison. Tesla had many revolutionary developments in

(i) Electromagnetism,

(ii) Invention of radio

(iii) AC motors

(iv) Polyphase distribution system.

There are many other

inventors which played an important part in field of electricity.

(a) James

Watt

(b) Andre

Ampere

(c) George

Ohm.

So it is unfair to name a single man for discoveries and

inventions in field of electricity. They have all made great contributions in

field of electricity through which we have such a great electricity system.

In 1936 it has been found

that ancient peoples have also experimented

with electricity, too. In 1936, a clay pot was discovered that suggests that the first batteries

may have been invented over 2,000 years ago. The clay pot contained copperplates, tin alloy, and an iron rod.

It could have been used to create an electric current by filling

it with an acidic solution, like vinegar. No one knows what the device was used for,

but it sheds some light on the fact that people may have been learning about

electricity long before Benjamin Franklin!

For generating electricity from fruits and vegetables visit link:-

http://electrialstandards.blogspot.in/2016/09/electricity-from-pototes-and-other.html

Saturday, June 18, 2016

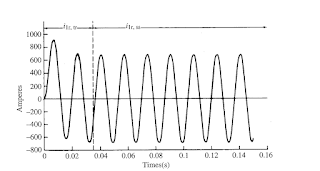

Locked rotor current calculations

Let’s take an example of motor having motor rating of 30 HP and rated current of 34.9A. With code letter of G. Now lets calculate the locked rotor current of the motor.