Types of Capacitors; Paper Capacitor; Mica Capacitor; Ceramic Capacitor; Electrolyte Capacitor; Oil Capacitor

Types of Capacitors:-

Capacitors

are classified according to type of material used as its dielectric, such as

paper, oil, mica, or electrolyte.

(A)

PAPER CAPACITOR

That kind of capacitor is made of flat thin strips of metal foil conductors

that are separated by waxed paper.

àRange is 300 picofarads -4 microfarads.

è

Voltage =600 volts.

In these

capacitors, Capacitors are sealed with wax to prevent the harmful effects of

moisture and to prevent corrosion and leakage.

There are

so many outer covering used in paper capacitors out of these simplest being a

tubular cardboard covering. Some types of paper capacitors are encased in very

hard plastic. These types are very rugged and can be used over a much wider

temperature range than can the tubular cardboard type.

(B)

MICA CAPACITOR

These type of capacitors are made of metal foil plates that are separated by sheets of mica. Mica is used as Dielectric medium. The whole assembly is encased in molded

plastic.

There are

following advantages of Molded plastic coverings:-

1. Corrosion and damage to the plates and dielectric are prevented.

2. Molded plastic case makes the capacitor mechanically stronger.

Mica is an

excellent dielectric and can withstand a higher voltage than can a paper

dielectric of the same thickness.

Ranges is

from 50 picofarads to 0.02 microfarad.

(C)CERAMIC CAPACITOR

This type

of capacitor is named as Ceramic capacitor because it contains a ceramic

dielectric.

There are

two types of Ceramic capacitors:-

1.

Hallow Ceramic Cylinder

In this

capacitor is named as Hallow ceramic cylinder capacitor as both the form on

which to construct the capacitor and as the dielectric material. The plates

consist of thin films of metal deposited on the ceramic cylinder.

2.

Disk Shaped Ceramic Capacitor

A second

type of ceramic capacitor is manufactured in the shape of a disk. After leads

are attached to each side of the capacitor, the capacitor is completely covered

with an insulating moisture-proof coating.

Range1

picofarad - 0.01 microfarad

voltages Range

is as high as 30,000 volts.

(D)

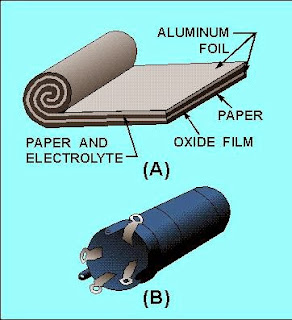

ELECTROLYTIC CAPACITOR

These

types of capacitors are used where a large amount of capacitance is required. In

these type of capacitors electrolyte is used as dielectric medium. Electrolyte

used in these capacitors may be in form of liquid. Liquid type electrolytic

capacitors are no longer used as care is needed to prevent spilling of

electrolyte.

A dry

electrolytic capacitor consists essentially of two metal plates separated by

the electrolyte.

In these

capacitors capacitor is housed in a cylindrical aluminum container which acts

as the negative terminal of the capacitor. The positive terminal is a lug on

the bottom end of the container.

Multi-section

electrolytic capacitor is illustrated in figure. In figure above there are four

capacitors enclosed in one capacitor. Four lugs shown above acts as positive.

Each capacitor is identified by an embossed mark adjacent to the lugs, as shown

in figure above.

Note the

identifying marks used are the

(a)

Half moon

(b)

The triangle

(c)

The square

(d)

No embossed mark.

By looking at the bottom of the container and the identifying

sheet pasted to the side of the container, you can easily identify the value of

each section.

Internal

construction of an electrolytic capacitor similar to paper capacitor. The

positive plate consists of aluminum foil covered with an extremely thin film of

oxide. This thin oxide film acts as the dielectric of the capacitor. Next to

and in contact with the oxide is a strip of paper or gauze which has been

impregnated with a paste-like electrolyte. The electrolyte acts as the negative

plate of the capacitor. A second strip of aluminum foil is then placed against

the electrolyte to provide electrical contact to the negative electrode. When

the three layers are in place they are rolled up into a cylinder as shown in

figure above.

An

electrolytic capacitor has main disadvantages as:-

Electrolytic

type capacitor has Low leakage resistance as it is polarized. This means there

are chances that positive plate be accidentally connected to the negative

terminal of the source as the thin oxide film dielectric will dissolve and the

capacitor will become a conductor.

As electrolytic

capacitors are polarity sensitive there use is restricted to a dc circuit only or

to a ac circuit where a small ac voltage is superimposed on a dc voltage.

Special

electrolytic capacitors are available for certain ac applications, such as a

motor starting capacitor.

Range of

Dry type capacitors is 4 microfarads - several thousand microfarads.

Working

voltage of approximately 500 volts.

(E)

OIL CAPACITORS

That type

of capacitor is often used in high-power electronic equipment. Oil filled capacitor is similar to Paper

capacitor only difference is that paper capacitor is immersed in oil. Since oil

impregnated paper has a high dielectric constant, it can be used in the

production of capacitors having a high capacitance value. Such a capacitor is

referred to as a SELF-HEALING capacitor.

For Knowing about fixed and variable capacitors visit here:-

http://electrialstandards.blogspot.com/2015/05/fixed-and-variable-capacitors-fixed.html

To know how capacitor stores charge visit link below:-

http://electrialstandards.blogspot.in/2015/05/what-is-capacitor-how-capacitor-stores.html

To know about capacitor series and Parallel operations visit link:-

http://electrialstandards.blogspot.com/2015/05/capacitor-in-series-and-parallel.html

For Knowing about fixed and variable capacitors visit here:-

http://electrialstandards.blogspot.com/2015/05/fixed-and-variable-capacitors-fixed.html

To know how capacitor stores charge visit link below:-

http://electrialstandards.blogspot.in/2015/05/what-is-capacitor-how-capacitor-stores.html

To know about capacitor series and Parallel operations visit link:-

http://electrialstandards.blogspot.com/2015/05/capacitor-in-series-and-parallel.html

Great article thanks for sharing.

ReplyDeleteAR Engineering, an ISO Certified Company. India’s Most Trusted Brand In Oil Filtration Machines, Oil Filtrations Plants, Varnishing Machines, Trickle Impregnation Technique, Batch Type Trickle Impregnating Machine, Industrial Oil Purification Systems, Vacuum Impregnations Plants

Index Type Trickle Impregnating Machine manufacturer in pune

Index Type Trickle Impregnating Machine suppliers in pune

Index Type Trickle Impregnating Machine exporter in pune

Index Type Trickle Impregnating Machine manufacturer in india

Index Type Trickle Impregnating Machine suppliers in india

Index Type Trickle Impregnating Machine exporter in india

Index Type Trickle Impregnating Machine

vacuum pressure impregnation plant exporter in india

vacuum pressure impregnation plant exporter in pune

You are doing wonderful job, I appreciate your efforts. Looking for more updates from your side.Thanx for sharing us.I would like to introduce our-self as a AR Engineering in Pune. For more updates, please look into our website.

ReplyDeletehttp://varnishingmachine.com/

Varnishing Machines exporters in pune

Trickle Impregnation Technique supplier in pune

Transformer Oil Filtration System in india

Industrial Oil Purification Systems suppliers in pune

Pressure Impregnation Plants

Index Type Trickle Impregnating Machine

Batch Type Trickle Impregnating Machines suppliers in pune

Nice post thanx for sharing with us

ReplyDeleteAR Engineering is leading manufacturer of Varnishing Machines manufacturer in pune ,Maharashtra, India. Transformation oil filtration machine in india, oil purification plants,Transformer oil filtration machines in pune.

Varnishing Machines suppliers in pune

Trickle Impregnation Technique manufacturer in pune

Transformer Oil Filtration Plants manufacturer in pune

industrial oil filtration plant

Vacuum Impregnation Plants

Index Type Trickle Impregnating Machine manufacturer in pune

Batch Type Trickle Impregnating Machine manufacturer in pune

Thank You Very Much For Great Post. Dc Capacitor do not play an important role in DC circuits because it is impossible for a steady current to flow across a capacitor.

ReplyDelete