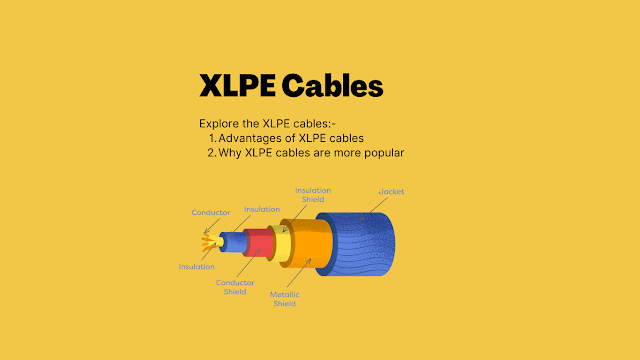

XLPE Cables Applications and Advantages

·

Why is XLPE cables are Cross-Linked?

In

XLPE insulation cables the rubber is vulcanized with addition of Small

quantities of chemical additives. This will help to rearrange the molecular

structure into a lattice this process will hinders the movement of molecules in

the presence of heat.

XLPE cable is insulated with hydronic

tubing made of cross-linked polyethylene plastic (XLPE). The XLPE

insulation has a three-dimensional bond within the plastic. The insulation is

a thermoset, zero halogen insulation that provides flame retardant

properties. It is strong, durable, and temperature conducting.

This

process of vulcanization is being carried out to increase the stability of the

XLPE cables even at high temperatures. This process of Cross-linking

polyethylene also improves current carrying capacity i.e. rating of XLPE in

order to withstand higher short circuits and under normal load conditions.

By

this XLPE insulation, the problem of increased aging as a result of electrical,

environmental and mechanical stress is taken care of as well. After Cross

linking these cables can be used in the open air or buried (for underground

distribution) with no affect on current rating and heating of cables.

The cross-linking creates a molecular

bond which improves a number of resistances such as:

- Heat

deformation

- Abrasion

- Chemical

- Stress

Crack Resistance

Various Applications

of XLPE Cables:-

There

is an endless list of usage of XLPE cable now days. Every industry uses these

cables according to their needs. Few of applications of these cables are as

below:-

Due

to ability of withstand extreme temperatures and pressure these are used in mines.

Even at these extreme temperature and pressure these still maintain its

toughness that makes it a suitable material for mines.

Advantages of

XLPE Insulated Cables:-

1. XLPE

insulated cables are perfect for High voltage transmission. This is due to its

insulation properties. These cables are better than the other alternative

options available in the market such as Silicon rubbers, and even Ethylene

Propylene Rubber, EPR.

2. These

cables have better moisture resistant.

3. These

cables are better chemical resistant.

4. These

cables are better oil resistant.

5. These

cables possess better mechanical properties

6. These

cables have better impact resistance.

7. These

cables possess better elongation.

8. These

cables have better tensile strength.

9. These

cables saves time and cost during installation, maintenance and repair works.

10. During

transmission of high voltage from one point to another we observe sparking,

shocking and heat that could cause fire or other potential hazards. In XLPE

cables are better used for such purposes to avoid such type of instances.

11. These

cables requires less maintenance. XLPE cables doesn’t melt when there are high

temperatures and thus XLPE cables can take excess load per unit are without

fracture or tearing.

XLPE cable tubes have shape memory

characteristics, which only require heat to return it to its original shape.

Cross-linking is a very intricate

process. XLPE raw material powder is formed and processed into sturdy, durable

end products, usually formed into cylindrical shapes that can be used for long

tubing.

If during the cross-linking process

the degree is too high, the material could become brittle and cause stress

cracking. If too low, the physical properties could be very poor and unusable.

Made correctly, the tubing can act as a strong, long-lasting insulator to

various wires and cables, protecting it from all sorts of external elements.

XLPE is designed to replace

traditional galvanized steel, copper, and PVC piping due to rusting, cost and

circulation. Cross-linking can solve plumbing issues at competitive pricing and

can sometimes be easier to install.

Some of important features of these

cables are listed below:-

·

Hydrolysis resistance.

·

High electrical & insulation properties.

·

High extrusion speed.

·

Heat resistance.

·

Sunlight resistance.

·

Moisture resistance.

.png)

Comments

Post a Comment